How to distinguish the shapes of Jianzhan bowls

A common feature of all Song Dynasty Jianzhan bowls is a larger diameter at the edges of the bowls and a smaller diameter at the base. There are three sizes of bowls: large (diameter at the edges of the bowl from 15 cm), medium (diameter at the edges of 11-15 cm) and small (diameter at the edges less than 11 cm).

There were also special standard-sized bowls used to determine the quality of tea leaves (the “doucha” procedure 3 ) and called “Shukouwan” (Chinese: 束口碗, pinyin: Shùkǒuwǎn, literally “Bowl with tied edges” ), the diameter of the edges of such bowls was a standard 13.5 cm.

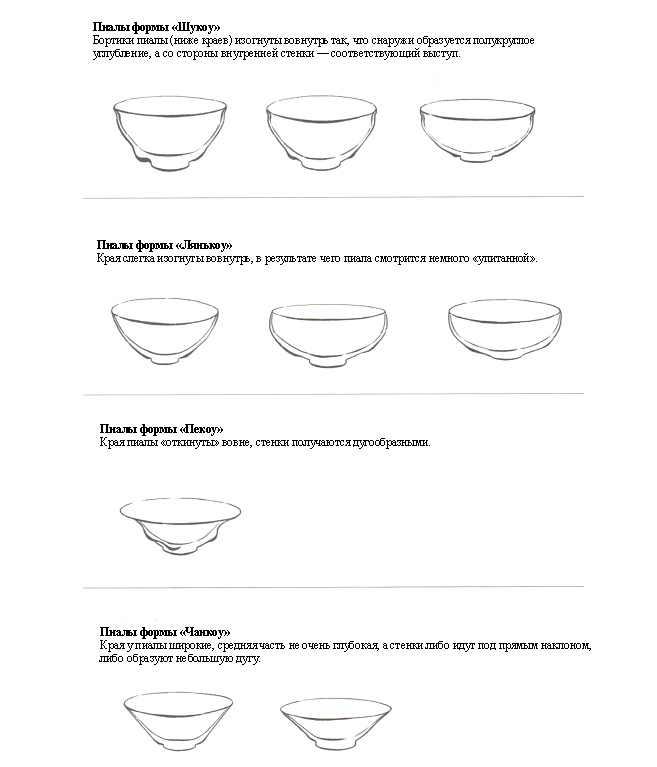

According to the classification proposed by archaeologists, all Jianzhan bowls can be divided into four types depending on the shape of the transition between the middle part and the bottom of the bowl: Shukou (Chinese: 束口, pinyin: Shùkǒu, literally "Tied edges" ), Liankou (Chinese: 敛口, pinyin: Liǎnkǒu, literally "Pull together edges" ), Pekou (Chinese: 撇口, pinyin: Piēkǒu, literally "Folded edges" ) and Changkou (Chinese: 敞口, pinyin: Chǎngkǒu, literally "Wide (open) edges" ). Of these, the most characteristic is the Shukou type, this beautiful shape was first created specifically for Jianzhan bowls.

"Iron clay"

Jianzhan bowls are famous for the fact that they are traditionally made from "iron clay" - clay with a relatively high iron content, mined in the vicinity of Shuiji village (Jianyang district). The iron content in such clay reaches 7-9%, due to which it can sometimes even be attracted to a magnet.

However, the iron content of each batch of clay varies slightly, so a magnet will not be able to verify whether a bowl is made from clay from that region - this applies to both new and ancient bowls. In addition, there are manufacturers who, in pursuit of the properties of "iron clay" , mix iron oxide into the clay in order to increase the overall iron content. Whether this violates the principle of naturalness, so important for Jianzhan bowls, is debatable.

Modern scientific experiments have shown that the clay of Jianzhan bowls contains minerals such as mullite, quartz, cristobalite and iron oxides, so it has been called "dark clay" or "purple clay" since ancient times. Even if there is insufficient iron in the glaze during the firing process, the iron contained in the clay can be fused into the surface of the glaze.

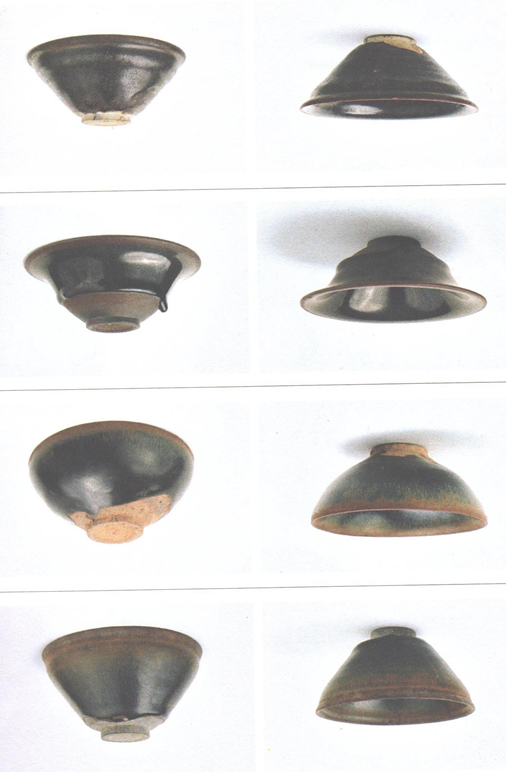

In Jianzhan bowls made of genuine “iron clay”, the areas not covered with glaze become grey-black after firing, and if such areas are of any other color, it can mean two things: either it is not “iron clay” at all, or it is indeed “iron clay” , but the firing temperature was insufficient - one can understand whether the firing temperature was the cause by comparative analysis of the glaze colors.

Another important point to note is that in the old days, the clay used to make Jianzhan tea bowls had a relatively high gravel content, which made the clay coarser and the unglazed areas rough to the touch, which is why it was sometimes called “Taosutai” (Chinese: 桃酥胎, pinyin: Táosū Tāi, literally “shortbread clay”). From a technical point of view, the presence of gravel in the clay can be explained by the fact that Jianzhan tea bowls require a firing temperature of 1300 °C, and if the clay is too fine, such a temperature will most likely cause the product to deform. In addition, the presence of voids in the coarse clay helps maintain the temperature of the tea in the bowl, which made it possible to hold the aforementioned tea quality competition (doucha).

Nowadays, many ancient Jianzhan bowls have been found during excavations of ruins of pottery villages or burial sites. Due to the fact that they are made of coarse clay with a large number of voids inside, a lot of substances adsorbed from the earth got into them, so ancient bowls can be collected, but can no longer be used as tea utensils. In modern Jianzhan bowls, the friction of the base of the bowl on the table surface is taken into account, so the clay is cleaned of small gravel more thoroughly. To avoid deformation of the products, many manufacturers first

The workpiece is shaped by pre-firing at a low temperature, after which glaze is applied and the piece is fired at a high temperature until ready.

Note 3: Doucha (Chinese: 斗茶, pinyin: Dòuchá, literally "tea scooping") was a tea quality competition that took place during the Song Dynasty, in which victory was determined by the slowest rate at which a tea leaf could be immersed in water.

- Comments

- Vkontakte