Long Yao - dragon kiln (Chinese: 龙窑, pinyin: Lóng yáo). Wood fired

In the Neolithic era, human ancestors discovered the value of fire and used it to create living utensils - primitive clay pottery, which significantly improves the quality of human life. Over the next thousands of years, people invented all kinds of kilns to fire more elegant pottery. About 3,500 years ago, in the middle of the Shang Dynasty, the technology of building dragon kilns was used, which had a larger capacity and could fire harder ceramics, the production of which began to be commercialized. Long Yao or Dragon Kiln (Chinese: 龙窑, pinyin: Lóng yáo) is a semi-continuous wood-fired kiln for firing ceramics or porcelain. It got this name because it looks like a reclining dragon. Nowadays, the dragon kiln is more of a cultural aspect, a tribute to tradition, since they have been replaced by gas and electric kilns.

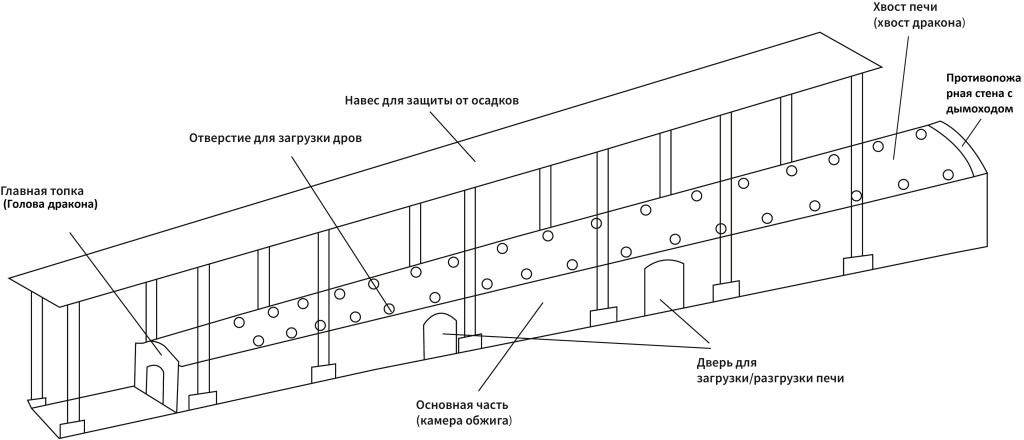

Composition of the Dragon Furnace

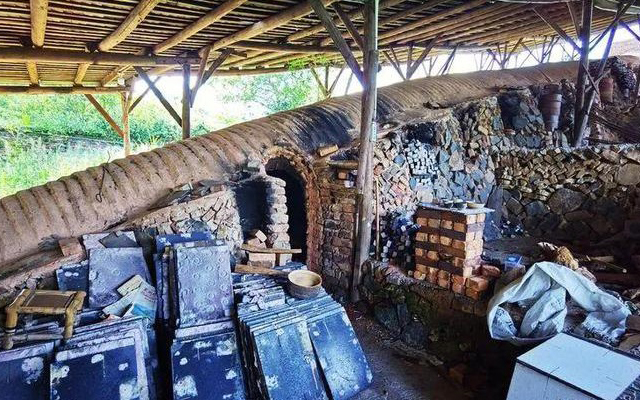

Dragon furnaces were always built on a gentle slope of a hill with an elevation angle of 15 to 30 degrees. With this arrangement, the hot air moves from the bottom up, and the thermal energy is fully utilized.

Dragon kilns are usually built of brick and have a sloped draft (the flames flow more or less horizontally, rather than up or down from the ground). The heat starts at the bottom of the kiln and moves up the slope. Firing times can be relatively short, about 24 hours for a small kiln, but usually cooking and cooling takes several days.

The whole furnace has a simple design, low construction cost and does not require arched bricks of strict dimensions. This furnace consists of 3 parts: the main firebox (the dragon's head), the firing chamber (the dragon's body) and the end part of the furnace with a chimney - the dragon's tail. The length of the furnace is about 20-80 meters (sometimes up to 100 m), the width is about 1.5-2.5 meters, and the height is about 1.6-2 meters.

The cross-sectional area of the kiln entrance (dragon head) is the smallest, which helps concentrate heat at the beginning of the kiln and facilitates combustion. The firing chamber is arched, and on both sides or at the top of the kiln there are rows of holes called "dragon scales". Firewood is added to these holes to regulate the kiln temperature, usually thin branches with a diameter of about 0.15 m.

They can also be used to observe the color of the fire and its behavior.

On both sides of the furnace body there are two doors for loading/unloading finished products. At the tail end of the furnace there is a so-called fire wall, which keeps the flame in the furnace itself. The "dragon tail" ends with a chimney. A dragon furnace, as a rule, does not have a chimney, or it is very short, since the structure itself with an elongated body acts as a chimney.

How the Dragon Furnace Works

The head of the stove is fired first, the wood is thrown in order from front to back and burned row by row.

Firing in such a kiln can be divided into two stages: heating the kiln and direct wood firing .

The launch of a dragon kiln is a grand event. Its operation requires a huge amount of firewood, time and people. Several weeks of preparation are required for this event, the kiln is prepared, firewood is brought in, and products are collected from all over the area for firing.

The firing operation of the dragon kiln depends entirely on the skill of the workers and is determined by visual observation of the changes in flame temperature. This requires highly skilled technology and rich experience. Since the color of the fire of the dragon kiln is only judged by experience, the workers on both sides must frequently exchange opinions about the fire, so that the temperature of the kiln is the same and the pottery on both sides is fired at the same time.

First, the flame is kindled in the dragon's head - the main firebox. Usually, coal is used for this, then the flame is fed with firewood. Burning coal as kindling takes about 20 hours; after the temperature reaches 400 degrees, the firewood is ignited "on the dragon's back" in turn through the scales on both sides of the dragon stove.

Each flake burns approximately 100 kg of firewood, the temperature begins to rise to at least 1170 degrees. The required firing temperature depends on the material and size of the fired product. Dragon's tail is used to fire large everyday ceramics (made from heavy sand).

The firing temperature is regulated by feeding firewood (usually pine branches due to high thermal energy), the dragon furnace can be heated to no more than 1300 degrees. Humidity and quantity of firewood, loading time, atmospheric pressure, ambient temperature, all this affects the overall firing process.

Uneven firing effects, obvious "fire spikes" (the effect of contrasting temperatures due to open flame) - these are the distinctive features of finished products that have been fired in a dragon kiln.

Unfortunately, firing of dishes in a dragon kiln creates a large percentage of defects - from 40%. This is a technological process that is quite difficult to control. Therefore, sometimes the products are fired in a "closed way", placing them in closed clay containers that protect them from open flame.

Ceramic firing is assessed by several criteria: degree of sintering, visual effect (color), graininess. The degree of sintering depends on the firing temperature and does not depend on the type of kiln. The effect of different firing types is manifested only in the visual effect and graininess, since these criteria are affected by the so-called "fire spikes".

History of the development of the dragon furnace

The firing process of Yixing clay ceramics has evolved from the Longyao dragon kiln (Chinese: 龙窑, pinyin: Lóng yáo), the inverted-flame kiln (Chinese: 倒焰窑, pinyin: Dào yàn yáo) to the tunnel kiln (Chinese: 隧道窑, pinyin: Suìdào yáo), etc. Among them, the dragon kiln has been used the longest. The fuel for the dragon kiln is pine wood, for the inverted-flame kiln - coal, in the tunnel kiln - petroleum products.

The high iron oxide content of Yixing clays requires high firing temperatures of about 1400 C, but since the clay also contains other elements: CaO, MgO, K2O, Na2O, the actual firing temperature is only 1150 ~ 1180 ℃. The difficulty of maintaining a high firing temperature forced craftsmen to constantly improve the technique and design of kilns. There were still a lot of defects, the surface of the products was covered with bubbles, was rough, and the dishes acquired an uneven color.

The Longyao dragon kiln was developed during the Shang Dynasty. During this period, the dragon kiln was used to fire everyday ceramics and celadon. A little later, the porcelain kiln was developed. The kiln size gradually increased, the structure was improved, as the products became more and more elaborate.

From the Shang Dynasty to the Ming and Qing Dynasties, the kiln was widely used in porcelain production in southern China (Jiangsu, Zhejiang, Guangdong, Fujian, Jiangxi and Hunan provinces).

In the middle and late Tang Dynasty, the classic dragon kiln is 20 meters long and has a slope of 10-28 degrees. At the end of the kiln, there is a fire wall, and at the bottom of the wall, there is a smoke hole. Using the principle of the difference in height of the slope, the heat rises naturally. The kiln of the Northern Song Dynasty had a narrower and shorter body. In the Southern Song Dynasty, the kiln body was widened and became longer, the bottom of the kiln was covered with sand, and the slope was small. Such kilns continued to be used during the Ming and Qing Dynasties.

Nowadays, dragon ovens have been almost completely replaced by electric or liquefied gas ovens.

There is only one genuine wood-fired Dragon Kiln in Yixing today. At one time, Yixing teapots fired in Dragon Kilns were sent to Ninjing, the Southern Capital. It was there that the entire cultural elite, capable of appreciating the level of such products, was concentrated.

Yixing Pottery Firing Today

Yixing clay teapots are fired not only in dragon kilns (Chinese: 龙窑, pinyin: Lóng yáo), but also in kilns with ejector plates (Chinese: 推板窑, pinyin: Tuī bǎn yáo) and electric kilns (Chinese: 电窑, pinyin: Diàn yáo). Thanks to modern kilns, finished products become more refined, allow all the qualities of clay to be revealed, and the percentage of defects is noticeably small.

The kiln with pusher plates got its name because the heat-resistant firing plate is driven by a hydraulic press. It is a tunnel-type kiln, divided into 3 sections: heating (inlet of the kiln), firing section and cooling section (outside the kiln) with a total length of more than 30 meters. It uses gasified or liquid fuel (petroleum products and natural gas). The kiln is half open, the air movement depends on the size of the opening and the atmospheric pressure.

The firing temperature is regulated semi-automatically. Firing racks are divided into open and closed, such a furnace provides eight temperature modes. From the entrance to the furnace to the exit from the furnace, 14 hours pass (the reaction time is about 1.5 hours). The products in such a furnace, as a rule, all have the same appearance, except for those placed on the upper open platform.

Electric oven - It is a closed furnace in which electrical energy is converted into heat. The firing process is closed.

There is no flame in the electric oven, so the finished product does not have "fire spikes" and looks very delicate. Since the resistance heating wire is installed on four walls and placed in the oven in several layers, the temperature difference in the electric oven varies greatly, and the temperature in the upper and side positions is the highest. It takes about 20 hours for the electric oven to reach its maximum temperature.