History of Tea Inspection in China

The birthplace of tea is China. The country still remains one of the largest tea producers in the world. The annual production volume in 2020 was 2.986 million tons, the area of tea plantations reached 3.165 million hectares, which is 62.1% of the total area of tea plantations in the world. With the gradual expansion of the market, much attention is paid to the quality characteristics of the product. The main way to determine the safety and quality of tea is inspection. The study of this issue is of great interest.

Tea testing has been around since it became a commodity, because the quality of the product is related to the health of consumers and personal safety. Since the Tang and Song dynasties, various methods of testing tea have appeared in China. The requirements for its quality are also constantly changing.

Tea inspection includes physical evaluation of the product and chemical analysis. Visual inspection usually includes organoleptic inspection, checking for tea dust and broken/crushed tea, packaging integrity, inspection for foreign matter, etc.; chemical inspection mainly includes checking the tea ingredients (moisture, ash, polyphenols, caffeine, amino acids, aroma, etc.), pesticides, heavy metals, etc.

Tea inspection takes place throughout the tea production process: at the stages of cultivation, processing, sales, scientific research and is an important means of maintaining the quality of tea and ensuring the safety of the product. There are safety standards with quantitative determination of various components in tea.

The beginning of the development of tea inspection in China.

1. The period of the emergence of tea supervision.

In ancient times, small peasant farming was dominant, and tea tax was an important source of government revenue, so the government attached great importance to the problem of tea adulteration and illegal trade. The country had strict laws against tea adulteration.

In the early years of the Tang Dynasty, the government began to tax tea production and sales. The prevalence of private production caused some losses in government tax revenue, so the government banned private tea farms. During the Song Dynasty, the production and sale of counterfeit tea was widespread, and the government took a number of measures to tighten controls on counterfeiting. During the Yuanfeng Period (the name of the reign of Emperor Zhao Xu (Song Dynasty)), a law was enacted on the grinding of tea in a water mill; during the Jianlong Period, the first law was issued prohibiting the sale of counterfeit tea.

2. The initial stage of development of tea testing.

The spread of counterfeit tea is linked to government policy and the commodity economy of the time. The Ming Dynasty Tea Law regulated the trade of tea and horses. The legislation was particularly strict in the provinces of Sichuan and Shaanxi, which led to huge disparities in tea prices across regions. This led to an even greater spread of counterfeit Chinese tea . Most of the laws passed in the early Ming Dynasty were related to the fight against private tea trade.

The law prohibiting counterfeit tea was not introduced until the Hongzhi Dynasty (reign of Emperor Zhu Yutang 1488–1505). During the Qing Dynasty, China established trade relations with foreign countries and tea trade became an important part of exports. The profitability of the tea business led to the widespread distribution of counterfeit tea.

Despite the efforts of the dynasties, tea inspection laws were unsystematic and limited.

After the Opium War in 1840, unscrupulous traders produced huge quantities of adulterated tea to increase profits: dyed, from used and low-quality raw materials. Due to the introduction of a ban on adulteration of tea by the British Parliament in 1869, China was forced to tighten controls on the export of the product, competing in trade with India and other countries.

In 1871, six active tea companies in Hankou established the "Hankou Tea Industry Administration" on their own initiative. In 1890, Emperor Zhang Zhidong opened the first public tea warehouse in Hankou to sample tea for quality control.

In 1896, the Ministry of Finance established the "Tea Policy Bureau" and the "Tea Association". Particularly effective was the supervision organized by local authorities in Zhejiang, Fujian and Taiwan, whose laws and regulations included various methods of punishment, including the burning of production facilities and confiscation of property through the courts.

In 1900, the South Taiwan Tax Statistics Bureau issued an announcement confirming the ban on counterfeit tea. The production and sale of such tea was strictly prohibited. Previously, inspection only existed for tea exports, and often consisted of tasting the drink by experienced tea masters, there was no detailed objective method and established standard for inspection. Before 1905, the Qing Dynasty government promulgated the "Tea Improvement Regulations", which stipulated various methods for growing and producing tea to ensure the safety and quality of the product.

Overall, tea inspection developed slowly during this period, addressing the problem of tea adulteration without quality control.

Stages of active development of tea supervision

1. The period of rapid development of tea inspection.

In 1911, the government began to establish special institutions to inspect the quality and formulate standards for tea exports, which improved the reputation and economic status of China's tea trade in domestic and foreign markets.

In 1914, Zhang Qian, the Minister of Agriculture and Commerce, formulated the “Regulations on the Methods of Classifying Tea” and the “Regulations on Tea Inspection”, which laid the foundation for China’s tea inspection system. In 1915, the first local pilot inspection agency organized by tea merchants (Chinese: 永嘉茶叶检验处, Yongjia Tea Inspection Office) was established in Wenzhou City, Zhejiang Province, marking the beginning of local tea export inspection work in China. In 1923, a pilot tea inspection laboratory was established in Taiwan, which became a symbol of the quality of Chinese tea exports.

In 1931, the Central Ministry of Industry issued the first official regulations for inspecting exported tea, the Export Tea Inspection Regulations (Chinese: 出口茶叶检验规程, pinyin: chūkǒu cháyè jiǎnyàn guīchéng). Thus, the minimum standard for green tea became loose leaf Bahàozhong (Chinese: 平水夏茶八号珠, pinyin: píngshuǐ xiàchá bāháozhū), and for red tea – Hunan Qihong (Chinese: 湖南次红, pinyin: húnán cìhóng). For other types of tea, the following indicators were identified as a minimum test: smell corresponding to the type of tea, humidity 8.5%, amount of tea dust 5-7%.

Subsequently, the Commodity Inspection Bureaus in Shanghai and Hankou successively carried out inspections in accordance with the "Tea Inspection Regulations" issued by the Ministry of Industry, which marked the beginning of regular national inspections on tea exports. In 1932, the inspection standards became more thorough, and different regulations were set for moisture content according to the type and grade of tea. The tea inspection standards between 1933 and 1935 remained roughly the same as those in 1932. In 1935, the Ministry of Industry promulgated the "Tea Inspection Regulations of the Commodity Inspection Bureau", which broadened the definition of substandard tea and limited the damage caused to tea quality by human factors. In 1936, the Commodity Inspection Bureaus of Shanghai and Hankou revised the regulations on tea inspection standards, and in 1937, the tea inspection standards were supplemented with a ban on tea coloring. By now, the tea testing system has been formed and used since the founding of New China (1949).

In 1936, the National Economic Committee held the National Conference on Tea Technology, proposed the inspection of tea origin, and promulgated the Ten Regulations on the Inspection of Tea Origins by the Ministry of Industry. In 1937, the Tea Origin Inspection and Supervision Bureau was established in Shanghai, and the Zhejiang, Anhui and Jiangxi provinces established tea origin inspection offices. In the same year, the Guangzhou Commodity Inspection Bureau set up commodity inspection offices in Fuzhou, Xiamen, and Fuding. However, due to the outbreak of the Anti-Japanese War, the inspection of tea origins and exports was difficult, and in 1938, it was transferred to the provinces.

2. Decline in tea inspection.

When the Pacific War broke out in 1941, tea exports were blocked and inspections were suspended. After the end of the Anti-Japanese War, local commodity inspection bureaus gradually resumed operations. In 1946, the liberation war broke out, tea exports were insignificant, and the development of tea inspection was slow.

3. Tea inspection recovery period.

In 1949, the People's Republic of China was established, but the country was in decline. In 1950, the Central Ministry of Commerce convened the first National Commodity Inspection and Administration Conference in Beijing, formulated national uniform temporary standards for export tea inspection, and decided to resume the inspection of tea origin. As a result, under the leadership of the Party and the government, tea inspection began to undergo a process of restoration. In 1951, the Shanghai Commodity Inspection Bureau held a national training course on tea inspection to integrate the principles of evaluation and inspection, inspection technology, and technical inspection work procedures.

In 1952, China banned the coloring of tea. In 1954, the Fujian Branch of China Tea Company and the Fuzhou Commodity Inspection Bureau in Xiamen jointly held a meeting to determine export inspection standards for black tea, green tea, oolong tea, and flavored tea.

The Interim Standards for Inspection of Export Tea were formulated in 1950, and were further revised in 1952, 1955, and 1960. In 1955, brick tea was excluded from the relevant tea category, and scented tea and white tea were added. In 1962, the “Interim Standard for Inspection of Export Tea” was officially introduced, which has become a comprehensive tea standard since the founding of the People’s Republic of China. This standard specifies moisture, powder/dust content, and packaging requirements for different types of tea. In 1964, the Ministry of Foreign Trade added oolong tea and scented tea to the list of export commodities subject to mandatory inspection. The creation of standards created jobs in the production and export areas.

The modern period of development of tea inspection in China.

1. Improving relevant institutions and policies in the field of tea inspection.

During the early period of Deng Xiaoping's reform and opening-up policy, tea inspection work was concentrated around the Hangzhou Tea Processing Research Institute of the Ministry of Commerce (now the Hangzhou Tea Research Institute of the All-China Federation of Supply and Marketing Cooperatives (Chinese: 中华全国供销合作总社杭州茶叶研究院, pinyin: zhōnghuá quánguó gōngxiāo hézuò zǒngshè hángzhōu cháyè yánjiūyuàn)), the Ministry of Agriculture of the People's Republic of China, the General Administration of Quality Supervision, Inspection and Quarantine, and local commodity inspection bureaus. In 1980, the initial inspection of export tea was moved to ports. In 1981, the Ministry of Foreign Trade and the General Administration of Commodity Inspection issued the "Ministry Interim Standard on Tea" (WMB48-81) and the "Technical Regulations on Sampling and Inspection of Export Tea", which specified the indicators. At the same time, the State Administration of Commodity Inspection issued the "Testing Rules for Inspection of Export Tea" to strengthen the scientific management of tea inspection. Since then, under the guidance of the State Administration of Commodity Inspection and Quarantine, orderly inspection of export tea has been carried out in all regions, which has made an important contribution to the improvement of China's tea inspection system.

In order to improve the efficiency and precision of tea inspection, from 1987 to 1990, the Ministry of Foreign Trade and the State Commodity Inspection Bureau organized and held several national tea inspection conferences and expert symposiums to discuss the organoleptic evaluation standards of export tea, the implementation of the "Interim Standard of the Ministry of Tea" and hygienic registration. In 1989, the Standing Committee of the Seventh National People's Congress enacted the Law of the People's Republic of China on Import and Export Commodity Inspection, indicating that the country's commodity inspection work had entered a new stage of legal management.

In 1988, the National Tea Quality Supervision and Inspection Center (now renamed the National Tea Quality Supervision and Inspection Center, affiliated with the Hangzhou Tea Research Institute of the All-China Federation of Supply and Marketing Cooperatives) was established. The National Tea Inspection Agency, accredited by the Committee and the National Laboratory in 1998, began to issue inspection reports that are recognized by the relevant institutions of the member states of the International Laboratory Accreditation and Cooperation (ILAC).

In 1998, the China Commodity Inspection Bureau, the China Health and Quarantine Bureau and the China Animal and Plant Quarantine Bureau merged into the State Import and Export Inspection and Quarantine Bureau, which coordinates and improves various types of inspection of tea imports and exports. In 2000, the Health Supervision Department of the State Import and Export Inspection and Quarantine Bureau held an expert group meeting on inspection of pesticide residues in exported tea, and drafted the "Notice on Further Strengthening the Supervision and Administration of Sanitary Inspection of Exported Tea" and related documents.

At the beginning of the 21st century, the systems and institutions for verifying the origin of tea and supervising its production licenses were improved. In 2001, the Ministry of Agriculture formally implemented the “Action Plan for Ensuring Organic Food” and established the origin identification and certification system for products, and successively promulgated agricultural industry standards and verification requirements for “pure” and “organic” tea in 2002 and 2003. In 2004, the State Council executive meeting adopted the “Regulations of the People’s Republic of China on the Origin of Imported and Exported Goods”, which came into effect the following year. At the same time, the General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China issued the “Notice on Seal and Issue of Review Rules for 13 Categories of Food Production Licenses, Including “Confectionery and Tea”. In 2005, the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China issued the "Notice on the Inspection and Management of Quarantine Documents for Export Tea Plantations", which stated that tea raw materials should come directly from planting bases registered with the inspection and quarantine authorities, which has been in effect since 2008. In 2006, the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China issued the "Detailed Rules for the Inspection of Tea Production Licenses", which specified 26 items for inspecting the quality of tea products.

In 2009, the promulgation and implementation of the Food Safety Law of the People's Republic of China marked a new stage in China's food safety. In 2012, the Zhejiang, Hunan and Fujian Provincial Entry-Exit Inspection and Quarantine Bureaus jointly issued the Import and Export Tea Inspection Regulations, which set out the methodology for determining and disposing of sampling, inspection and inspection results for import and export tea, which is still in use today. In 2018, the State Administration of Quality Supervision, Inspection and Quarantine was no longer included in the institutional reform plan of the State Council.

Since then, the tea inspection work has been clearly divided into the following three parts: the main responsibility lies with the State Administration for Market Regulation for the inspection of tea sampling, inspection and testing capacity of inspection and testing institutions, inspection of tea production license, etc. The General Administration of Customs is mainly responsible for entry-exit sanitary quarantine, inspection and quarantine of animals, plants and their products, and statutory inspection of import and export goods; the State Intellectual Property Office is responsible for the inspection of geographical indications of tea.

In 2021, the Ministry of Agriculture and Rural Affairs, the State Administration of Market Supervision and Administration, and the All-China Federation of Supply and Marketing Cooperatives jointly issued the "Guidelines for Promoting the Healthy Development of the Tea Industry", indicating that during the "14th Five-Year Plan" period, six major measures will be taken to strengthen the tea industry, including measures such as strengthening management, supervision services, and strict market access.

Thus, the China Tea Inspection Authority has established a comprehensive system of institutions and laws to ensure the dynamic development of China's domestic and foreign tea trade.

2. Updating the indicators and methods of physical and chemical control of tea.

With the development of science, the methods for determining the physical and chemical indicators of tea have been constantly updated. At the national standard level, in 1983, the Shanghai Import and Export Commercial Inspection Bureau, the Tea Research Institute of the Chinese Academy of Agricultural Sciences and the Hangzhou Tea Processing Research Institute of the Ministry of Commerce jointly developed 13 physical and chemical testing methods for tea. The testing method standards were put into effect in 1987. They mainly covered tea sampling, preparation of ground raw material samples and their dry matter content, moisture, total tea dust, water-soluble and water-insoluble dust, alkalinity, crude fiber, broken tea content, caffeine, polyphenols, total free amino acids, etc. The methods for determining the physical and chemical components have been rapidly updated as the research deepens. For example, in 1983, there was only one method specified for the determination of moisture, the arbitration method or the 103 ℃ ± 2 ℃ weighing method (arbitration method); In 2002, the national standard "Tea Infusion" added the 120°C drying method (rapid method) as the second method for determining the moisture content of tea leaves. In 2016, "Determination of Tea Moisture Content" was included in GB5009.3-2016 "National Standard for Determining Food Moisture Content", which states that there are four methods for determining the moisture content of tea, namely direct drying, vacuum drying, distillation and Karl Fischer method. In 1987, the standard for the determination of physical and chemical components: caffeine, polyphenol and free amino acids was first published. In 2002, the method for determining caffeine was revised and high-performance liquid chromatography on the original basis was added. In 2013, the scope of the standard was expanded. The standards for determination of tea polyphenols were revised in 2002, 2008 and 2018, with the 2008 edition having changed the most. A method for determination of catechins by high-performance liquid chromatography was developed. The standard for determination of amino acids in tea was released in 1987, and its format and content were improved in 2002 and 2013.

The inspection standards were replaced by national food safety standards in 2017.

In order to meet the needs of the tea market development at home and abroad, as well as high standards of food quality and safety, a method for determining polyphenols and amino acids in tea has been developed. Currently, the following methods are used to detect caffeine: gas chromatography, liquid chromatography-mass spectrometry, spectrophotometry, near infrared spectroscopy, wave layer scanning.

The methods for determining tea polyphenols include spectrophotometry, electrochemical analysis, spectral analysis, mass spectrometry, chromatography, etc.; the methods for determining catechins mainly include high-performance liquid chromatography, thin-layer chromatography, gas chromatography, etc.; the main methods for determining total free amino acids are ninhydrin colorimetry, and the methods for determining amino acid components include post-column derivatization ion exchange chromatography, pre-column derivatization high-performance liquid chromatography, ACCQTag method, capillary electrophoresis method, gas chromatography, liquid chromatography-mass spectrometry, liquid chromatography-evaporative light scattering detector method, etc.

In general, methods for detecting physical and chemical indicators in tea are constantly being improved and developed in the direction of more accurate, fast, and effective analysis of the product properties.

3. Improvement of tea testing standards including judgment standards and method standards.

In 1979, the Central Ministry of Health issued the National Food Hygiene Research Plan. In 1981, the Hygiene Standard of Green and Black Tea GHn144-1981 was formulated, and the Hygiene Standard of Tea GB9679-1988 was revised and issued in 1988. This revision canceled the item on testing arsenic and heavy metals and incorporated it into the standard GB9674-1988 "Limits of Contaminants in Food".

Since the 1970s, the most important object of testing the quality and safety of tea has been pesticide residues and heavy metals. As early as 1972, the government banned the use of 666 and DDT in tea plantations; in 1984, a ban was imposed on highly toxic pesticides with high residues. In the 1990s, China banned the use of more than 20 types of pesticides on tea trees. By 2020, China had banned the use of 59 types of pesticides and chemicals. Since joining the WTO, the requirements for testing pesticides in tea have been steadily tightened. In the 2005 edition of the national food safety standard GB2763, tea contains only 9 pesticide residues, which has been revised five times in 2012, 2014, 2016, 2019 and 2021, the latest version GB2763-2021 includes up to 106 kinds of pesticide residues. At present, China's pesticide limit standards are ahead of those of other developing countries in the world.

The technology of pesticide detection in tea is constantly improving. In the early 1970s, thin layer chromatography was used to analyze organophosphorus pesticides: imidophos and dimethoate. In the 1980s, gas chromatography and liquid chromatography were the main methods of pesticide residue analysis, which were mainly used to detect organochlorine and pyrethroid pesticides widely used in tea plantations. In the 21st century, tandem chromatography-mass spectrometry has become the main tool for pesticide residue monitoring, residue behavior, and risk assessment studies. At this stage, the detection technology of pesticide residues in tea is relatively mature. GB23200.113-2018 for gas chromatography mass spectrometry detects 208 kinds of pesticides in plant products, and GB23200.13-2016 and GB23200.121-2021 make liquid chromatography mass spectrometry detect 448 pesticides and related chemical residues in tea. Such serious analysis has been widely applied. At present, the rapid detection technology of pesticides in tea mainly includes ELISA method, quantum dot lateral flow immunoassay, ion mobility spectrometry and surface enhanced Raman spectroscopy.

In 2005, with the abolition of the "Tea Hygiene Standard" GB9679-1988, the heavy metal index of tea was included in GB2762-2005 "Limits of Contaminants in Food", which abolished the copper content requirements and introduced the heavy metal index, a new indicator of the rare earth element limit. Later, in the "National Food Safety Standard issued in 2017, the limit of rare earth elements in tea was abolished. At present, the limit standards for heavy metals in tea are mainly the national food safety standard GB2762-2017 "National Food Safety Standard Limits for Contaminants in Food" and the standard of the Ministry of Agriculture NY659-2003 "Chromium, Cadmium, Mercury, Arsenic and Chloride in Tea" and NY/T288-2018 "Green Tea", the corresponding limits of heavy metal content are: lead 5.0mg/kg, chromium 5.0mg/kg, cadmium 1.0mg/kg, mercury 0.3mg/kg, arsenic 2.0mg/kg.

Tea safety supervision also monitors the improper use of food additives and dyes. The 2001 Agricultural Standard NY5017-2001 "Environmentally Friendly Tea and Products" stipulates that all kinds of environmentally friendly tea should not have any synthetic chemicals and flavorings added. According to GB2750-2014 "National Food Safety Standard for the Use of Food Additives", food additives and non-food raw materials are not allowed in the production of tea. For example, it is illegal to use industrial dyes such as lead chrome green, lemon yellow, sunset yellow, amaranth, carmine, royal blue and a number of others in production. In the National Tea Supervision and Sampling Regulations organized by the State Food and Drug Administration, the detection method of added pigments (dyes) in tea is in accordance with GB5009.35-2016 "Detection of Synthetic Dyes in the National Food Safety Standard". At present, the detection method of additives in tea is high-performance liquid chromatography. The work consists of two steps: the first is the pre-treatment of the sample, that is, the extraction and purification of synthetic dyes, the second is the analysis and determination of the additive.

Similar to food additives, the analysis of microorganisms in tea in the 1980s was mainly based on food testing standards, such as GB / T4789.2-1984 "Microbiological Testing of Food Hygiene", GB / T4789.3-1994 "Food Hygiene" "Microbiological Control of Escherichia coli" and GB / T5009.1-1996 "Food Hygiene Inspection Methods, Physical and Chemical Parts, General Rules". In 2001, the Ministry of Agriculture issued NY / T456-2001 "Jasmine Tea", which specified that the amount of E. coli bacteria in this variety should not exceed 500MPN / 100g (ml). In 2004, amendments were issued stipulating that the amount of Escherichia coli found in tea should not exceed 300MPN/100g (ml). In 2008, the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China issued GB/T22111-2008 "Geographical Indication of Pu'er Tea Product", which specifies the permissible amount of E. Helicobacter, Staphylococcus aureus, hemolytic streptococcus and other pathogenic bacteria. There are also corresponding standards for the analysis of colonies of beneficial bacteria, which play an important role in forming the quality characteristics of Pu'er tea, stipulating their minimum content. At present, the microorganism-related indicators in food safety standards include the total colony count of coliforms, mold and yeast, pathogenic bacteria, etc., and the limit values of the indicators are different for different foods.

Prospects

The purpose of tea inspection is to improve production and develop trade. The activities of inspection organizations are entirely aimed at improving the quality of tea, and, therefore, its competitiveness in the world market.

With the development of science and technology, tea testing methods will become more sophisticated, as close as possible to scientific, systematic, standardized analysis.

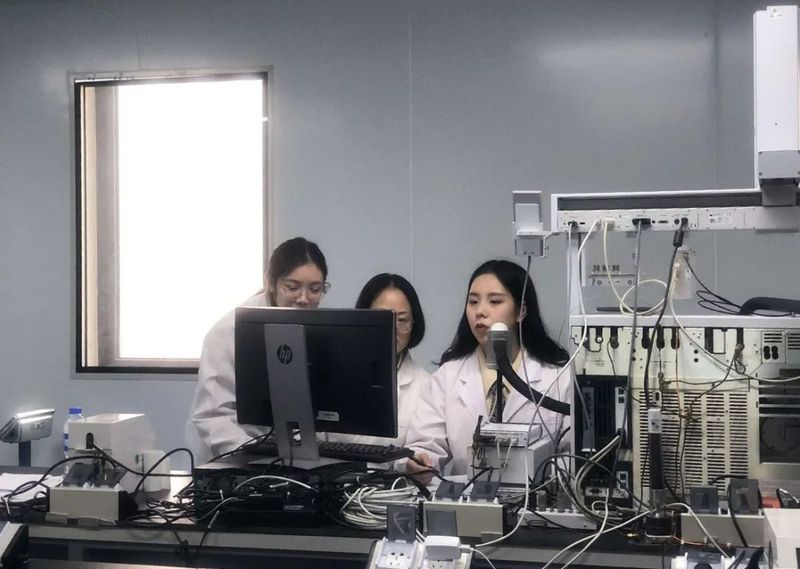

About the author: Anqi (Chinese: 安琪, pinyin: Ān qí)

Master of Anhui Agricultural University, whose main research focus is tea quality assessment and control. Author of seven scientific articles, member of the National Natural Science Foundation of China.

Under the leadership of Dai Qianying (Chinese: 戴前颖, pinyin dài qiányǐng)

Professor of Anhui Agricultural University, expert in tea industry. Engaged in teaching and research in the field of organoleptic evaluation of tea and quality control. Led research projects in Anhui Province funded by the state. Participated in 973 projects, developed two national standards, published more than 30 articles in domestic and foreign journals.

Source: China Tea Processing

https://m.puercn.com/news/124804/

- Комментарии

- Вконтакте